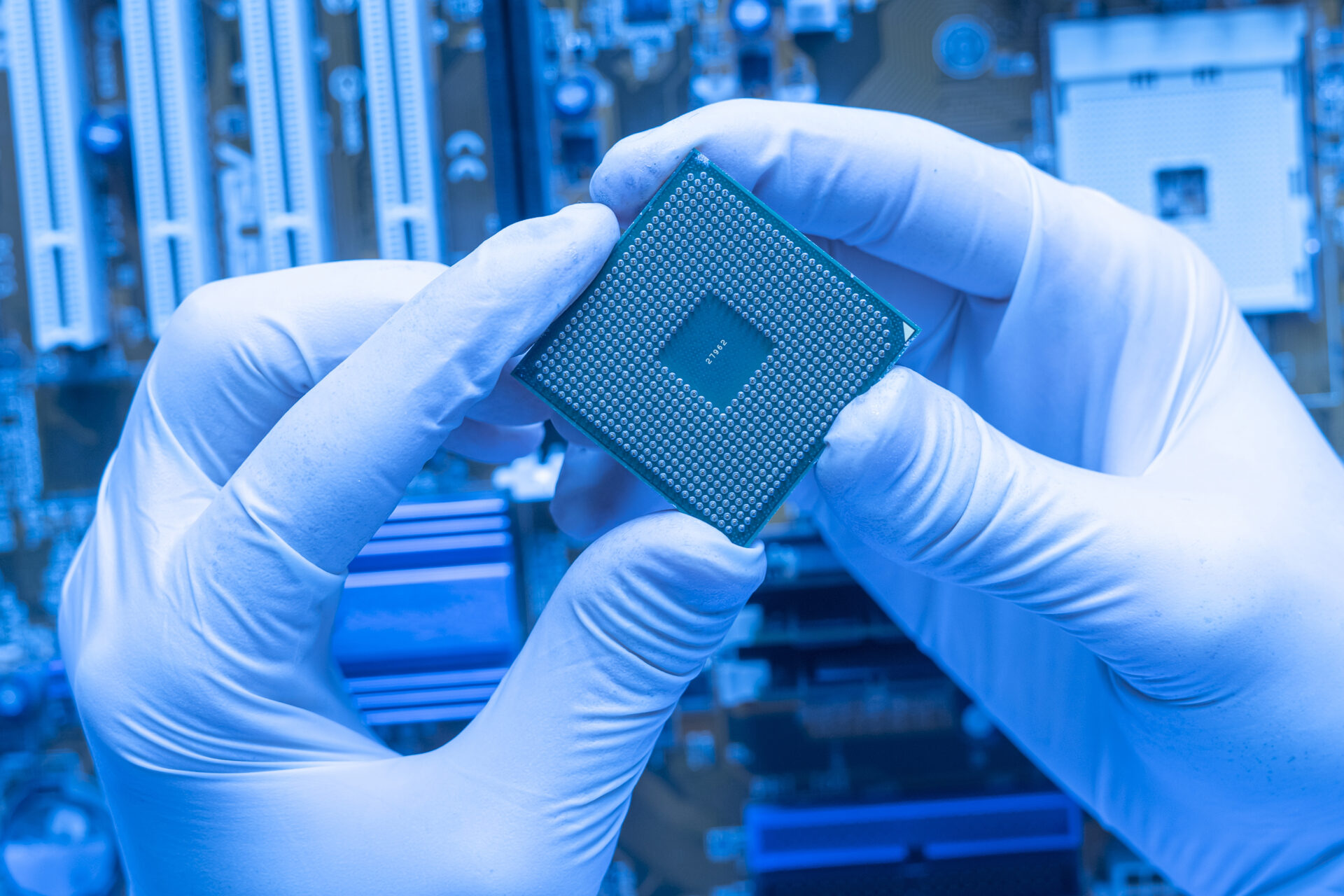

The Semiconductor Supply Chain Crisis: A Catalyst for Change

The global semiconductor supply chain crisis has exposed a critical vulnerability in modern industry. From electronics and automotive manufacturing to renewable energy and defense, global economies rely on a stable semiconductor supply — yet production capacity has not kept pace with skyrocketing demand.

The semiconductor industry’s ambitious goal to double global chip manufacturing capacity in the coming decade hinges on faster and more efficient fab construction. However, traditional on-site construction methods remain slow, fragmented, and labor-intensive.

To meet future demand, the sector must adopt innovative construction strategies — chief among them, Off-Site Manufacturing (OSM).

Why Off-Site Manufacturing (OSM) Matters in Semiconductor Construction

Leading chipmakers such as Intel, TSMC, Bosch, and AT&S are already investing in mega-fab projects across the globe. These projects are complex undertakings, where speed to market, quality assurance, and cost control are paramount.

Unfortunately, many fab builds are still hampered by outdated construction models. OSM provides a modern, technology-driven alternative — one that combines prefabrication, modular assembly, and digital design tools to dramatically improve project efficiency.

Key Benefits of OSM for Semiconductor Fabs:

- Accelerated project timelines through prefabricated subsystems

- Higher quality control via manufacturing in controlled environments

- Reduced site congestion and labor risk

- Improved cost predictability and supply chain resilience

Prefabrication and Modular Construction: Speed Meets Precision

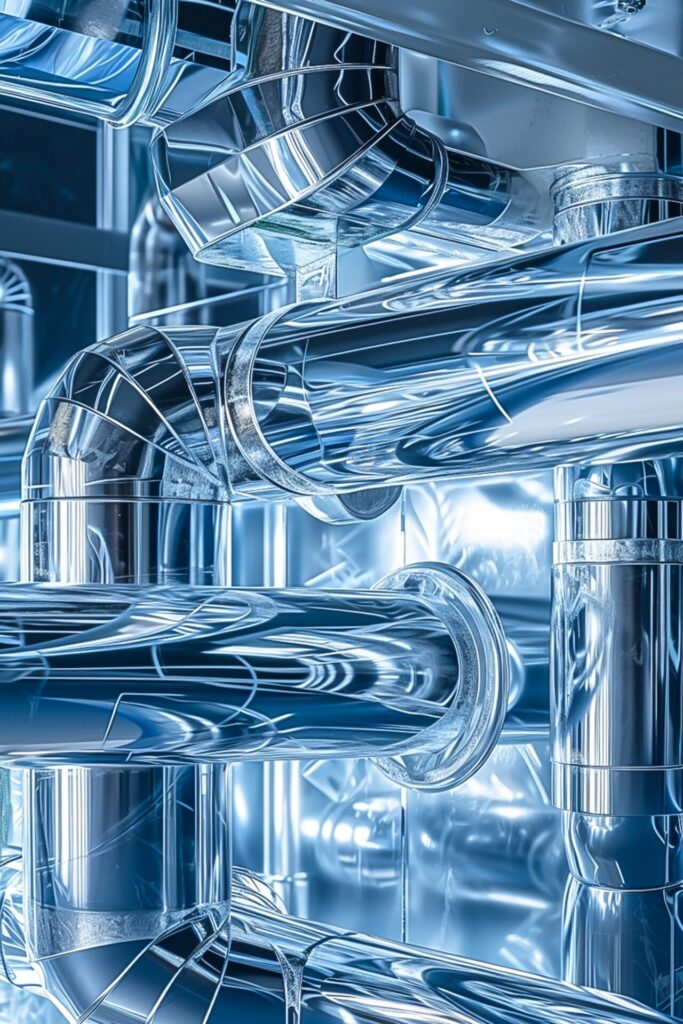

Fab construction involves some of the most sophisticated systems in the world — particularly in fluid management, vacuum, and gas distribution networks. Building these systems on-site is slow and error-prone, requiring specialized expertise that’s increasingly scarce.

Prefabricated and modular fluid system assemblies, produced off-site, change that dynamic entirely:

- Faster installation: Modules arrive fully assembled and tested, drastically cutting on-site labor and installation time.

- Improved reliability: Each system is tested for leaks, moisture, and pressure before delivery.

- Lower costs: Fewer connection points reduce potential leak risks and material waste.

Every hour of downtime in a semiconductor fab can cost millions. OSM helps minimize that risk, ensuring facilities reach full production capacity sooner and stay operational longer.

Interface Connectors: Reducing Delays and Boosting Time-to-Market

OSM also introduces standardized interface connectors, allowing installations to proceed even before key equipment arrives. This modular readiness minimizes disruption from overseas shipping delays or supply interruptions — a recurring challenge since the COVID-19 pandemic.

By decoupling system installation from equipment delivery, fabs can reach commissioning and ramp-up phases far faster, directly supporting the industry’s time-to-market objectives.

Digital Construction and BIM: The Foundation of OSM

Building Information Modeling (BIM) is at the core of modern OSM practices. BIM enables digital twin modeling, allowing engineers to design, coordinate, and test systems virtually before a single component is manufactured.

BIM advantages for semiconductor fab construction:

- Early detection of design clashes and spatial conflicts

- Improved collaboration across global engineering teams

- Reduced material waste and rework

- Enhanced safety and planning accuracy

For complex systems involving valves, regulators, fittings, and tubing, BIM ensures precision routing and integration — reducing costly design errors and ensuring long-term system reliability.

Lifecycle Efficiency: Extending the Value of Digital Design

The benefits of BIM and OSM continue throughout a facility’s entire life cycle. Detailed digital data can be integrated into maintenance, repair, and operations (MRO) processes, improving both uptime and cost efficiency.

Digitally documented assemblies simplify maintenance, reduce downtime, and extend system lifespan — supporting sustainable fab operation and higher overall equipment effectiveness (OEE).

Quality, Compliance, and Standardization in OSM

In semiconductor construction, precision and purity are non-negotiable. Off-site manufacturing ensures these standards by producing assemblies in controlled environments, where quality assurance testing — including leak, oxygen, and moisture validation — is performed before shipment.

This standardized approach:

- Guarantees repeatable quality

- Meets or exceeds the strictest semiconductor construction standards

- Enables specialized suppliers to focus on their area of expertise

The result is a more resilient and specialized supply chain, ready to deliver at the scale the industry demands.

Addressing Labor Shortages Through Off-Site Solutions

The global construction industry faces a growing shortage of skilled labor, particularly in high-tech sectors like semiconductor fabrication. OSM reduces on-site dependency on scarce skilled trades by moving labor-intensive work into advanced manufacturing environments.

This shift not only mitigates labor risks but also enhances safety, predictability, and scalability — all critical factors in delivering the next generation of semiconductor fabs.

The Future Is Modular: A Call to Action

The semiconductor sector stands at a pivotal moment. To meet rising demand and global economic expectations, it must reimagine how fabs are built.

Off-Site Manufacturing (OSM), combined with digital design and modular prefabrication, is not just a construction trend — it’s a strategic imperative.

Clients and project owners can lead this transformation by demanding OSM-based solutions that deliver faster, safer, and more efficient semiconductor facilities.

Change may challenge traditional methods, but the long-term productivity, sustainability, and competitiveness gainsare undeniable.

Learn More

Explore how our Off-Site Manufacturing solutions for semiconductor fab construction are helping leading chip manufacturers build faster and smarter.