The Global Construction Labor Shortage: A Persistent Challenge

The construction labor shortage has been an industry-wide concern for decades — and the situation continues to intensify. After the Great Recession of 2008, many skilled tradespeople left the industry and never returned. Meanwhile, younger generations have shown little interest in entering what is often seen as an unstable and physically demanding field.

The COVID-19 pandemic further strained an already depleted workforce. Today, the average skilled construction worker is over 50 years old, and for every five workers leaving the industry, only one new entrant replaces them.

At the same time, labor costs are at record highs, with over two-thirds of construction firms reporting continued increases. Recruiters face growing difficulty filling positions, putting additional pressure on timelines and project delivery.

For the semiconductor industry — where every delay translates to millions in potential revenue loss — this challenge is particularly acute.

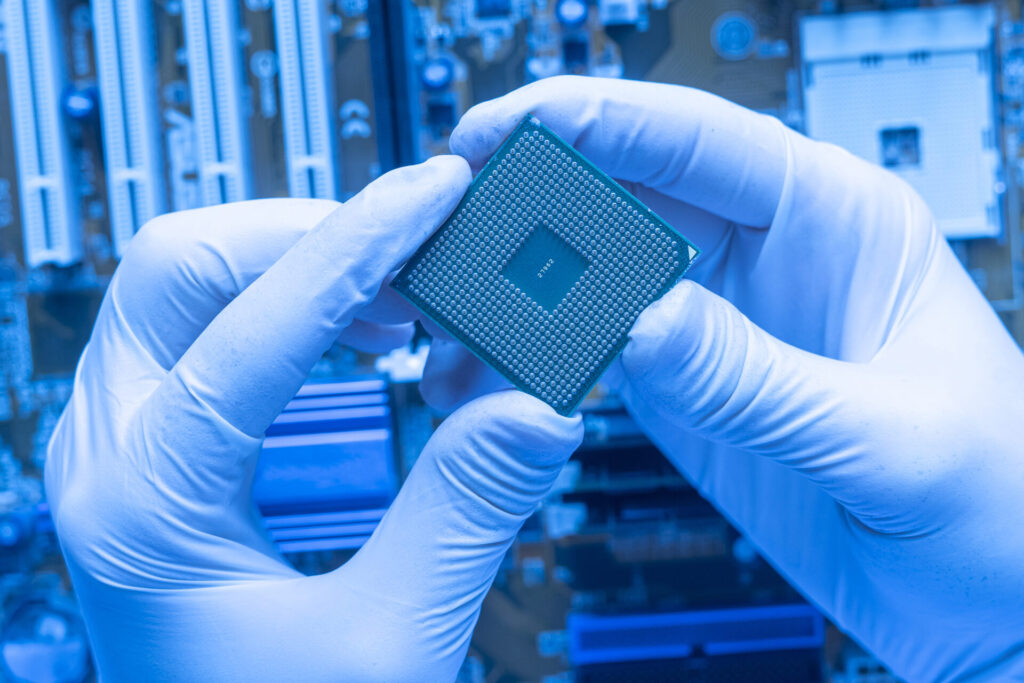

The Semiconductor Conundrum: Building Complexity Meets Workforce Scarcity

Constructing a semiconductor fabrication plant (fab) requires one of the most specialized workforces in the world. These projects demand precision, technical expertise, and strict adherence to safety and cleanliness standards.

However, the reliance on traditional on-site construction methods has led to unpredictable workflows, extended timelines, and stagnating productivity. As global chip demand soars, the need to reduce manpower dependency while maintaining the highest quality standards has never been greater.

A 2020 Boston Consulting Group report emphasized that access to skilled talent is one of the most critical factors when selecting a location for a new fab. While that study focused on operational staffing, the same principle applies to the design and construction phase — without skilled builders, fabs cannot come online fast enough to meet market needs.

The Cost of Delay: Lessons from the TSMC Arizona Project

A striking example comes from TSMC’s advanced chip plant in Arizona, where a six-month construction delay was attributed largely to a shortage of skilled labor. With fierce competition from other semiconductor giants such as Intel, recruiting and retaining qualified workers has become increasingly difficult.

These labor shortages have created a ripple effect: tighter project bids, shorter schedules, and shrinking profit margins. For contractors and suppliers, the path forward lies in process innovation — integrating methods and technologies that reduce on-site labor requirements and improve build efficiency.

Safety Concerns: New Workers, New Risks

A shrinking labor pool also introduces new safety risks. Construction job sites are inherently hazardous, and the influx of inexperienced workers increases the potential for accidents.

According to research from the Institute for Work & Health, employees in their first month on the job face three times the risk of injury compared to more experienced peers. These incidents not only endanger workers but also lead to costly project delays, reputational damage, and compliance issues.

Reducing the number of personnel required on-site — and shifting high-risk activities to controlled manufacturing environments — is an essential step toward safer, more efficient fab construction.

Prefabrication: A Smarter Solution to the Labor Shortage

One of the most effective strategies to counteract the labor shortage in semiconductor fab construction is prefabrication(or “prefab”).

Prefabrication involves manufacturing components off-site in a controlled facility, then transporting them to the job site for assembly. This approach enables construction firms to leverage their most skilled and experienced workersefficiently, while minimizing the need for large on-site teams.

Prefab also leads to cleaner, safer, and quieter construction sites, with fewer trucks, less noise, and minimal waste — aligning with sustainability goals and ESG priorities across the semiconductor industry.

While some argue that prefabrication reduces design flexibility, the trade-off is minor compared to the time, safety, and cost advantages it brings to complex, large-scale projects.

The Top 5 Benefits of Prefabrication in Semiconductor Construction

- Reduced Labor Risk

Prefab directly addresses the shortage of skilled trades by reducing the amount of on-site labor required. Controlled off-site production enables higher productivity with fewer people, while allowing experienced professionals to work more efficiently in specialized facilities.

- Improved Safety

By shifting complex fabrication work away from the construction site, prefab significantly reduces on-site congestion and potential safety hazards. A cleaner, organized factory environment allows for better oversight, fewer accidents, and improved worker well-being.

- Cost Savings

Transporting pre-assembled modules is typically less expensive than deploying large crews and resources to build from scratch on-site. Prefabrication minimizes rework, reduces material waste, and eliminates many of the hidden costs of field assembly.

- Time Savings

Multiple studies have shown that prefabrication can shorten construction schedules by up to 25%. Faster project delivery means fabs can begin production sooner — a crucial advantage in a market where time-to-market directly impacts profitability.

- Superior Quality Control

Factory-based assembly allows for stringent testing and inspection, ensuring each module meets exacting semiconductor standards before arriving at the site. This level of quality assurance is difficult to achieve with traditional field construction.

The Results: Proven Efficiency and Measurable Gains

Project owners adopting prefabrication have reported:

- Up to 10% savings in total project cost

- 25% reduction in schedule duration

- 16% decrease in fall hazard exposure

- 90% reduction in construction waste

These figures demonstrate that prefabrication and off-site manufacturing aren’t just temporary fixes — they represent the future of semiconductor facility construction.

Building the Future of Fab Construction

As labor shortages continue to challenge the global construction industry, prefabrication and modular constructionoffer a clear and sustainable solution.

At Lesico Process Piping, our mission is to deliver faster, safer, and more efficient fab construction by prefabricating the majority of process piping and mechanical systems off-site. This approach allows semiconductor manufacturers to accelerate project delivery, improve safety performance, and reduce total cost of ownership.

Learn More

Discover how Lesico Process Piping is helping the semiconductor industry overcome the labor shortage through innovative prefabrication and off-site manufacturing solutions here.