The Growing Labor Shortage in Construction

The labor shortage in the construction industry has been an escalating challenge for decades. After the Great Recession of 2008, many skilled tradesmen left the industry—never to return. Meanwhile, younger workers viewed construction as unstable and unattractive, leading to an aging workforce and widening talent gap.

The COVID-19 pandemic added even more pressure, amplifying delays, costs, and staffing challenges. Today, the average age of a skilled construction worker exceeds 50, and for every five tradesmen who retire or leave, only one new worker replaces them.

Adding to this crisis, labor costs have reached record highs. Over two-thirds of construction firms report rising wages and recruitment difficulties, with no signs of relief in sight. As a result, project timelines, profitability, and quality standards are under significant strain.

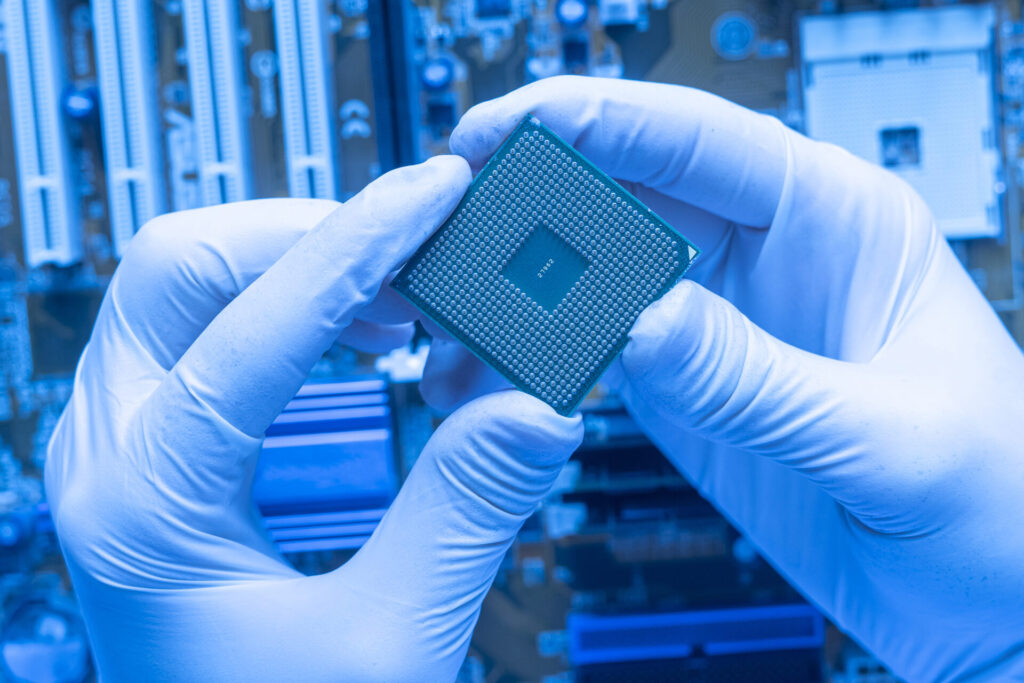

The Semiconductor Construction Conundrum

Nowhere is this shortage more evident than in semiconductor fabrication plant (fab) construction. These projects require highly specialized skills, making workforce recruitment exceptionally difficult.

Traditional on-site “stick-building” methods have led to unpredictable workflows and stagnant productivity. With global demand for new fabs accelerating, reducing manpower requirements has become critical.

According to a 2020 Boston Consulting Group report, access to skilled talent is one of the most important factors when selecting a fab location. While that study focused on operational expertise, the same applies to design and construction capabilities needed to build these advanced facilities.

Delays and Rising Competition

Recent reports from Nikkei Asia highlight a six-month delay in the construction of Taiwan Semiconductor Manufacturing Co. (TSMC)’s first advanced chip plant in Arizona. The setback was largely due to a shortage of skilled labor and intense competition from other tech giants like Intel.

As competition for qualified fab workers intensifies, project bids are becoming more aggressive, timelines are shrinking, and profit margins are tightening. To stay competitive, contractors must balance speed, skill, and efficiency—all while maintaining safety and quality.

For chip manufacturers, delays translate to massive financial losses. This pressure has construction firms seeking innovative solutions to reduce dependence on limited human resources.

The Safety Challenge of New, Inexperienced Workers

In an industry as dynamic as construction, safety risks are unavoidable—and the influx of inexperienced workers only heightens them.

According to research by the Institute for Work & Health (Toronto), employees in their first month on the job are three times more likely to experience a lost-time injury compared to those with a year of experience. These incidents not only disrupt projects but also harm company reputations and morale.

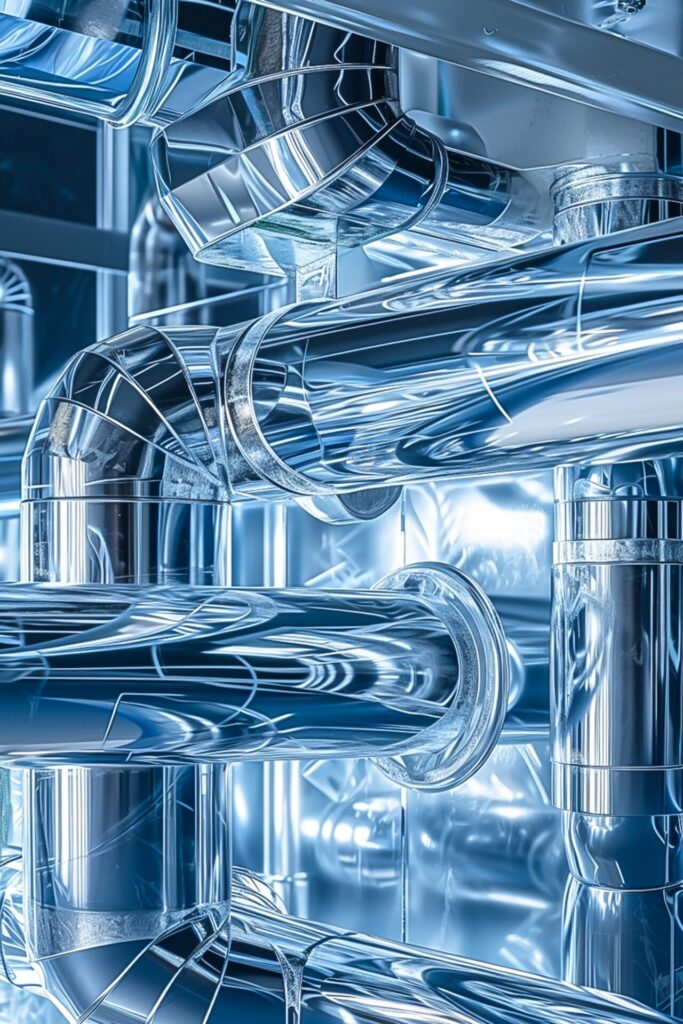

Prefabrication: A Smarter Solution for Modern Construction

To address labor and safety challenges, the construction industry has increasingly turned to prefabrication (prefab)—a method where structural components are manufactured offsite and then assembled onsite.

Prefabrication helps companies build more with fewer workers by optimizing efficiency and reducing onsite complexity. Fewer workers onsite means less congestion, less waste, and fewer accidents—all while maintaining high precision and quality control.

Although prefab may slightly reduce design flexibility, the benefits far outweigh this trade-off for most commercial and industrial projects, including semiconductor facilities.

Top 5 Benefits of Prefabrication

- Reducing Labor Risk

With skilled labor in short supply, prefabrication minimizes onsite workforce needs and accelerates project timelines. This helps contractors meet deadlines without compromising quality or safety.

- Increased Safety

By shifting complex assembly work to controlled factory environments, prefabrication reduces site congestion and the risk of accidents—especially for less experienced workers.

- Cost Savings

Transporting pre-assembled modules is often more cost-effective than coordinating on-site builds. Prefab minimizes rework, errors, and downtime, resulting in significant cost reductions.

- Time Efficiency

Studies show that prefabrication can reduce project timelines by up to 25%, helping firms overcome delays due to weather, labor shortages, or supply disruptions.

- Enhanced Quality Control

Offsite manufacturing allows for stringent quality assurance using factory-grade tools and consistent production standards—leading to more reliable outcomes and safer job sites.

Proven Results with Prefabrication

Project owners leveraging prefabrication have reported impressive results:

- Up to 10% cost savings

- 25% schedule reduction

- 16% decrease in fall hazard exposure

- 90% reduction in onsite waste

At Lesico Process Piping, our mission is to deliver faster, safer, and more efficient construction through advanced prefabrication methods. By completing the majority of work offsite, we help clients overcome labor shortages, improve safety performance, and meet demanding project schedules—especially in high-tech industries like semiconductor manufacturing.

Learn More

To see how Lesico Process Piping can help streamline your next industrial or semiconductor project, visit our Industry Page here.